Custom Moulding: Start to Finish

September 12, 2016

Using a computer-aided design (CAD) program we are able to be more accurate than ever.

The process starts with our new CNC machine from CNC Technology, Inc.

Here is a closer look at the metal being ground.

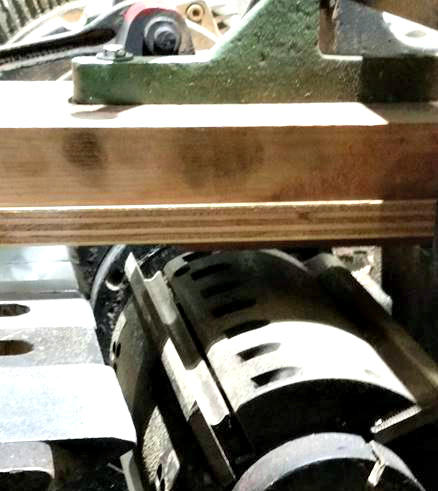

The carved knife is added to a moulder header and is then attached into the moulding machine.

A piece of lumber is run through the moulder and the knife carves out the inverse pattern of the knife profile.

The finished product: a sample moulding.

Here is the plastic pattern and the inversed sample moulding piece. Recent projects and clients utilizing our moulding services include the San Francisco Presidio (Boyett), and the historical restoration of Nystrom Elementary School (Roebbelen), which required replication of over 50 patterns. Contact us today to see how custom molding can benefit your next building project!